They might not be household names but Renishaw, Delmatic and DC Electronics are among the unsung heroes of British industry that are exploiting their technical skills to capture significant global markets.

Major players such as Renishaw and Oxford Instruments have relied on innovation, lean manufacturing and a commitment to overseas customers to stake their place in the world, while family-run businesses have benefited from the support of UK Trade & Investment (UKTI), the government department created to boost exports.

Exports account for 94 per cent of sales at Renishaw, which produces components designed to make manufacturing smarter and more efficient at its Gloucestershire headquarters and smaller plants in South Wales and Ireland.

China, where it first opened an office 20 years ago with two desks and a borrowed printer, now generates £75m in sales out of an annual turnover of £347m. The company started by selling high-end laser calibration products to universities and government agencies but as the country embraced automation, demand grew for a wider range of technical components.

Chris Pockett, head of communications, says: “The temptation was to deal through distributors but we recognised early on that we had to be on the ground to show commitment, provide support for our highly technical products and to understand as much as possible about our customers.” That commitment has now extended across the globe, with 60 offices in 32 countries.

Underlying Renishaw’s success is continued investment in research and development (14 per cent of turnover last year) and a determination backed by legal actions to protect the intellectual property of its innovative products.

Pockett adds: “We make smart products in the smartest possible way, stripping out costs at every opportunity. For example, the ratio of man to machine at our machine shop in Gloucestershire is one to six.” The company was hit by the global recession, reducing the workforce to 1,850 in 2009, but it has now grown to 3,300.

Oxford Instruments scores two points more than Renishaw, with 96 per cent of its revenues from exports, spread in equal proportion between Asia, Europe and the US. The UKlisted company, with a turnover of £350m last year, has grown by focusing on countries where governments and private industry invest in science and engineering and where new technology will make a difference.

The company now has wholly-owned enterprises in China, Japan and India, and head offices in Germany and the US. Sales to India grew by 56 per cent last year and in China have increased from £5m a year to £80m.

Its best-selling products include a hand-held X-ray metals analyser which determines the content of a piece of metal in seconds, a process that used to take two days. It was used to test the soil for hazardous substances at the site of the London Olympics.

Oxford Instruments is also supporting the growth in nanotechnology and capitalised on a decision by the Taiwanese government to equip schools with a table-top scanning electron microscope so that nanotechnology will become a part of every child’s education.

DC Electronics, run by David Cunliffe and his wife Sandra, are among smaller UK companies to have made an impact overseas. After building a business in Essex making wiring looms for race and rally cars, they believed expansion opportunities existed in the US but did not want to use an overseas distributor.

With the help of Simon Fennelly, a UKTI adviser with experience of the US market, they made contacts in the motor sport industry. It was then that NASCAR, the national body running racing, decided that cars should in future run on fuel injection engines.

Cunliffe says: “It was a key time for us and we ended up with immediate business from the States because suddenly that sector of motor sport did not have an established supplier base for the requirements of running by fuel injection.”

With races taking place almost every weekend for 10 months, it was essential for DC Electronics to have a manufacturing base in the US and with further advice from Fennelly, set up in North Carolina. In seven years, exports have increased from 10 per cent of the company’s business to 80 per cent, turnover has doubled and the company employs 17 staff.

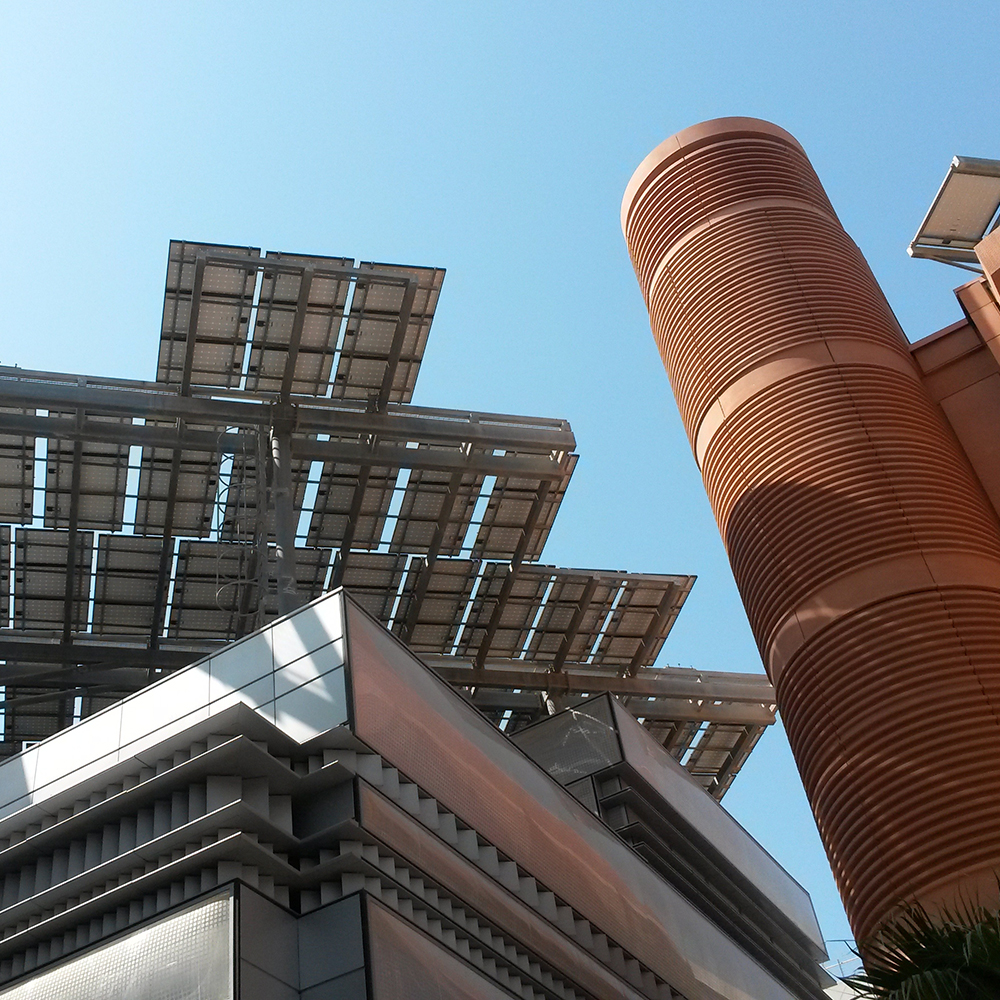

Major contracts have also been won in the Gulf states by a family-run London business, again with advice and support from UKTI in setting up and operating internationally. Delmatic, founded by John Woodnutt with his son Stephen as managing director, specialises in advanced lighting and energy efficient systems, including generating power from renewable sources, for rail and infrastructure projects.

In addition to providing systems for the Kings Cross station redevelopment, Crossrail and the Shard in London, Delmatic has set up subsidiary companies in Dubai, Abu Dhabi, Qatar and Saudi Arabia. These companies have won contracts to supply advanced lighting management systems for all 47 stations of the Dubai Metro, an energy optimisation system for a new zerocarbon, zero-waste city in Abu Dhabi, and worked on the Saudi rail network: yet more success stories for British engineering abroad.

Table talk:

“You can’t get to big from small without being mid-sized. It is one of those laws of nature. When you are small it is all about risk. When you are big you can afford risk. But when you are in the middle you have no capacity for risk because all you are trying to do is survive.”

— David Bott, who advises companies on how to grow at the Technology Strategy Board

“We have to get back the prestige of the highly-skilled technician — culturally it has been lost. A Royal Navy ship can go to sea without its chief professional engineer. But it cannot go to sea without its highly-skilled technicians.”

— Philip Greenish, chief executive of the Royal Academy of Engineering and a former Royal Navy engineer who retired as a Rear Admiral

“This is a critical industry for the British economy. There can often be a lot of hand-wringing in the country, especially about the issue of skills, but the message from this round-table is one of optimism.”

— Ian King, Business and City Editor of The Times

Original article